Sustainability

Opportunities & Challenges

Deliver a building that meets today’s sustainability goals and deliver a building that also meets your vision for design and performance.

With the rise in climate change events and increased stakeholder pressures, integrating sustainability measures and green building materials into your designs is more important than ever.

To help you design for sustainability without sacrificing beauty and functionality, Protean’s architectural metal wall panel systems contribute to a high-performance building envelope and can help your project achieve LEED credits within both LEED v4 and v4.1. In addition, our products support green building design in many ways.

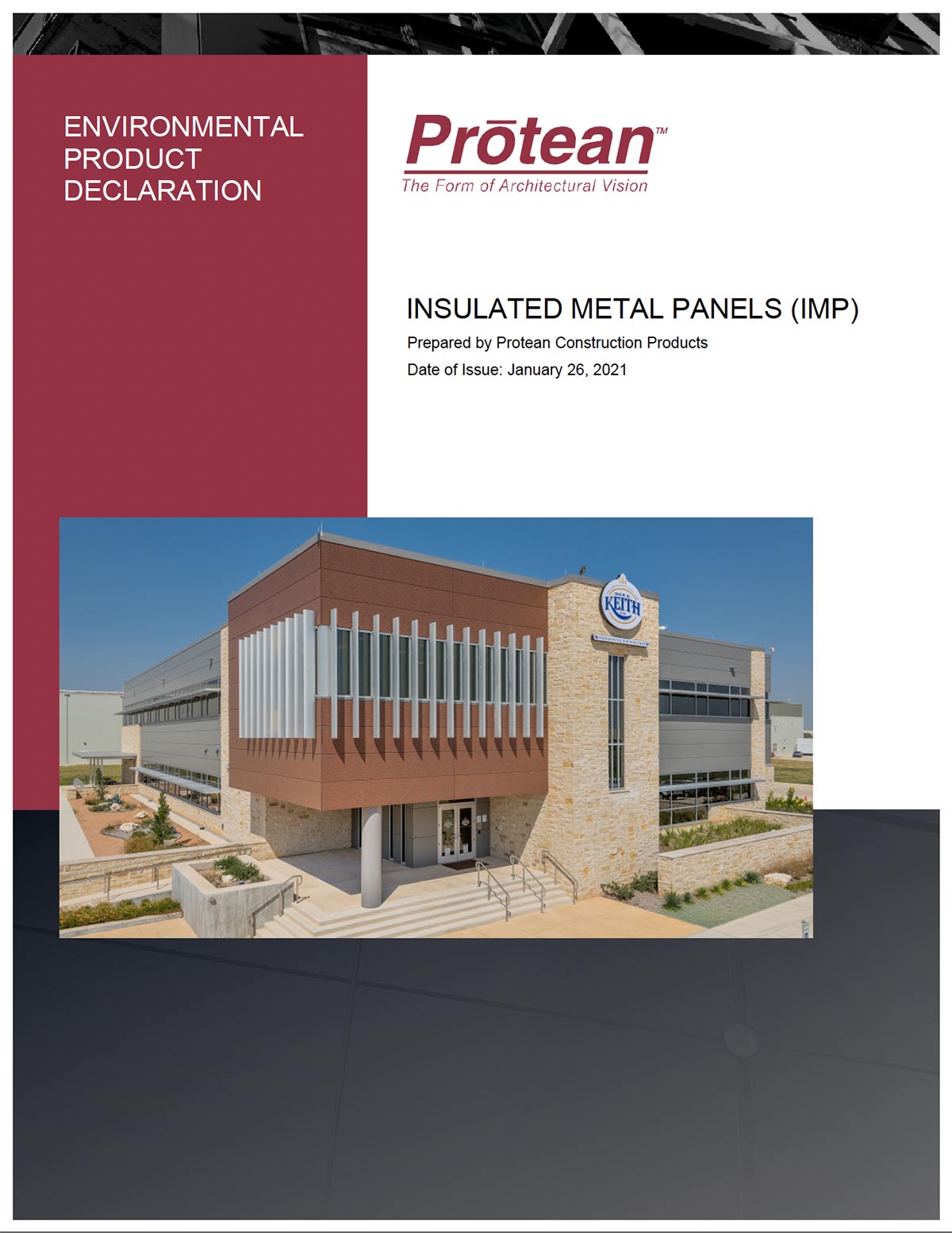

Chobani Innovation & Community Center

Twin Falls, Idaho

Protean's insulated metal panels

helped Chobani achieve both its sustainability and aesthetic design goals for this important new facility on their campus.

Protean's insulated metal panels

helped Chobani achieve both its sustainability and aesthetic design goals for this important new facility on their campus.

Sustainable Advantages

of Protean architectural metal panels:

- Post-consumer recycled content of 85% or more

- Aluminum plate and honeycomb panels are 100% recyclable at their end of use

- All metal waste from manufacturing is recycled

- Insulated metal panels increase energy efficiency of the building envelope

- Available in colors that meet requirements for a reduction in heat island effect

- No plastics in many of our products

- The high level of recycled content in Protean’s products qualify for credits

- Project locations located within 100 miles of our manufacturing facility qualify for additional credit

Questions?

952.895.4000